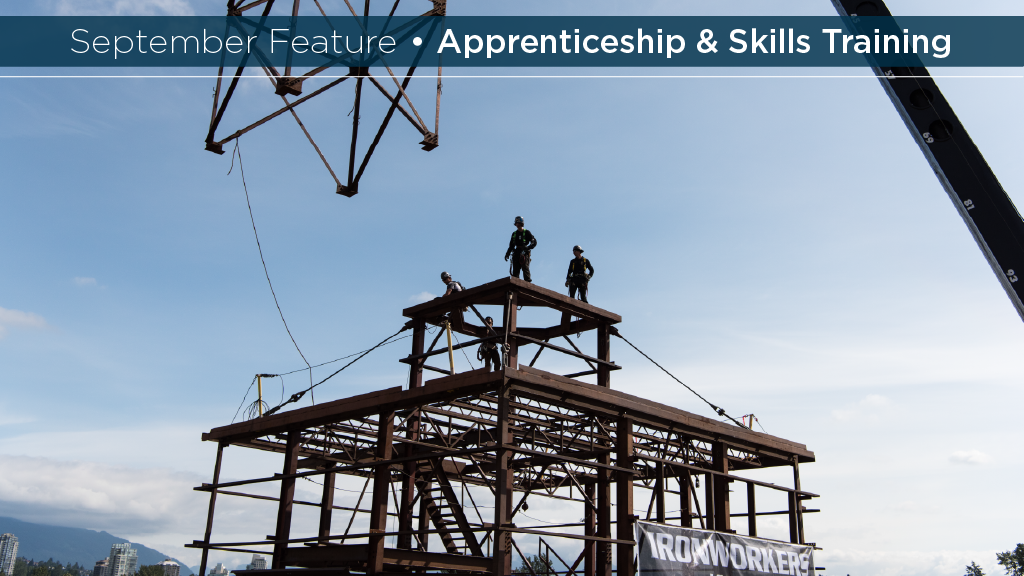

The British Columbia Institute of Technology (BCIT) in Burnaby, B.C. is building a replacement for its existing multi-storey, structural steel training facility called the Ironworker Tower.

The tower serves the generalist ironworker programs, part of which involve students assembling and dismantling the structure as a capstone project near the end of their time, says Mike McKoryk, head of BCIT’s Department of Steel Trades.

“On average, the tower runs four cycles per calendar year,” says McKoryk.

��������ed in the 1960s, around the same time that BCIT itself was built, the current tower has reached the end of its useful life as a training aid and needs to be replaced.

“As far as I know, the replacement tower will be the only one of its kind in the world,” says McKoryk. “The existing structure is already unique in North America.”

The ironworkers who work on present-day construction sites require different skills in order to deal with multiple materials and be able to troubleshoot the problems that arise when multiple materials meet in one structure, says McKoryk.

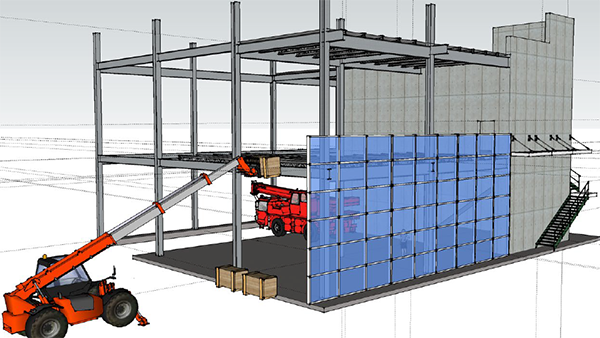

The replacement tower – currently just known as the collaborative hybrid living lab – will simulate a construction project in progress.

“The new tower will be a hybrid structure consisting of a lateral structural steel resisting brace and mass timber on a concrete base,” says McKoryk. “The existing tower was built 60 years ago according to Imperial measurements – a 10-foot-by -0-foot grid – which make the structural steel connections hard to work with now.”

The replacement tower will be a six-metre-by-six-metre grid, approximately 20-feet-by -20-feet.

“It’s time to move on to current industry practices,” says McKoryk. “Having a hybrid structure means we will be able to see how different materials interact.”

The project will be what McKoryk calls “a dynamic model of construction” and will be designed in such a way that it can be put up and taken down several times during the school year.

The goal of the project is to demonstrate an approach to multi-material construction that takes into account the whole system, rather than just its individual parts, and emphasizes the interconnectedness of all of the components.

Having a partially constructed structure on a simulated construction site gives a succession of steel trades students the opportunity for valuable applied learning.

In addition to having the opportunity to contribute to building the replacement tower, students from other departments, such as the design, engineering and construction management programs, will also be able to work on the new tower as part of their course work.

McKoryk says working on the tower is an effective way for students to learn.

“Our current structure provides us with plenty of evidence that the best way to learn is through doing,” he says. “As the scale of this project is both broader – hybrid material and interdisciplinary – and deeper – larger and taller bays – it will provide a variety of simulated construction challenges for learners to work through in as close to real world conditions as possible in education.”

McKoryk says BCIT students will be able to learn a lot from working on the tower that they couldn’t do without it.

“Working with a variety of materials enables learners to become acquainted with their special handling characteristics, tolerances and advantages and disadvantages, as well as a variety of techniques and tools,” says McKoryk.

Learning in an interdisciplinary environment also gives students the opportunity for “richer communication in a variety of modes,” by making them work with other students who are outside of their normal peer groups and classrooms.

Some preliminary design work to move the existing Ironworkers Tower has already been done.

The current phase of the project is focusing on engaging departments and programs outside of the steel trades.

“We want to engage BCIT stakeholders to find out who could benefit and what would be the ideal resource for them to have,” says McKoryk. “This could include programs and departments that do not typically collaborate with the steel trades, such as civil engineering, building science and construction management, as well as most construction trades. The scope and scale of the project makes it unique in the world of education.”

The source of the idea for the new tower came from conversations between McKoryk and a colleague.

“Ryan Downey and I have been bouncing a similar idea around for close to 12 years,” says McKoryk. “It was initially born out of the necessity to replace our ageing structure with something that we knew would be more reflective of current industry standards.”

Recent Comments

comments for this post are closed